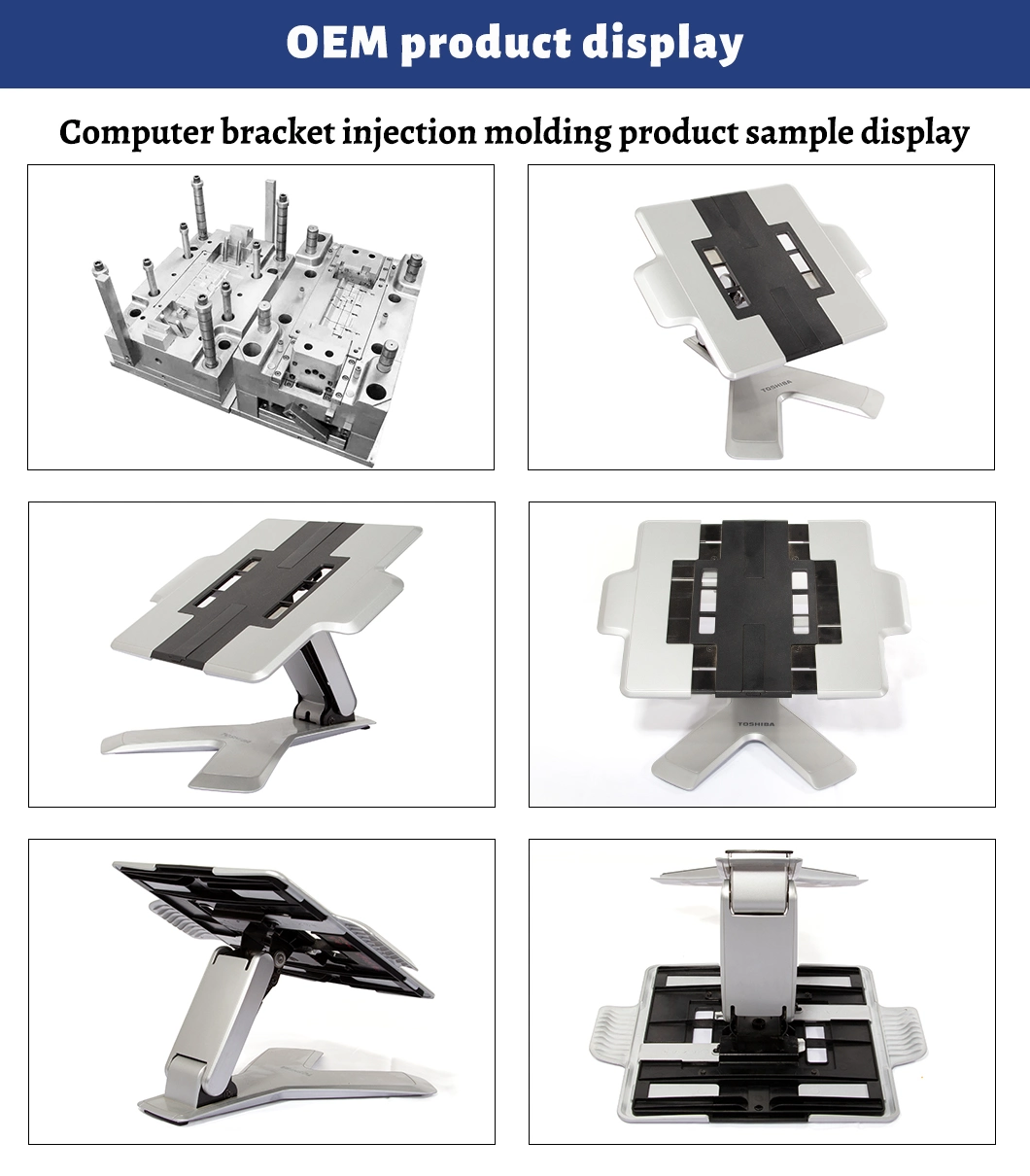

Export Hot High-Grade Light Luxury Professional Custom Medical Grade Classic ABS Plastic Silver White Black Universal Laptop Bracket CNC Injection Mold Molding

Depending on the structure of the plastic mold, it generally consists of a mold frame, a mold kernel, ancillary parts, a;

Basic Info

| Model NO. | HSK14100 |

| Application | Office |

| Color | Black |

| Material | Plastic |

| Packing | Customized |

| Meet Vesa | Customized |

| Transport Package | Customized |

| Specification | customization |

| Origin | China |

| Production Capacity | 600 Sets/Year |

Product Description

| Product Name | Computer Plastic Injection Molding Part | Product material | ABS,PP, Nylon,PC or any other material as you need | ||||||||||||||

| Place of Origin | Guangdong,China | Tonnage | 80-1300T | ||||||||||||||

| Type of enterprise | Professional manufacturer of injection molds andplastic parts | Production ability | 10,000pcs/day | ||||||||||||||

| Service | ODM,OEM,Design based on your idea or Make mold and produce based on your drawing | Package | Standard carton, pallet or customized | ||||||||||||||

| Size | As Custom's Requst | Prototype | 3D printing, CNC, Laser cutting etc. | ||||||||||||||

| Shipping way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air | Drawing format | Step., igs., x_t, dwg, pdf, stl(for 3D print)etc. | ||||||||||||||

| Assembly & Test | Five production department | Design software | Solidworks, Pro-E, UG, CAD, Rhino etc. | ||||||||||||||

| Payment details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc | surface | As Custom's Requst,heat treatment.polishing, texture,coating,etc | ||||||||||||||

1. Mold frame:

In general, we do not need to design and can order directly from the standard mold manufacturer, greatly saving the time required to design the mold, hence the name plastic mold standard mold. It forms the most basic frame part of the plastic mold.

2. Mold kernel

The core part is the core part of the plastic mold and is the most important part of the mold..The forming part of a plastic product is in the mould, and most of the processing time is spent on the mould..However, in contrast to some relatively simple moulds, it has no moulding part and the product is formed directly on the template..Early plastic moulds were mostly of this type, and were relatively backward.

3. Auxiliary parts:

The auxiliary parts commonly used in plastic molding are positioning rings, injection mouth bushing, thimbles, grasp pins, support columns, ejector plate guide column sleeve, garbage nails, etc..Some of these are standard parts that can be ordered directly together with the molding frame, and some require their own design.

4. Auxiliary system:

There are four auxiliary systems for plastic molding: a pouring system, an ejection system, a cooling system and an exhaust system..Sometimes, because the plastic material used needs to be heated at very high temperatures, some moulds will have a heating system.

5. Auxiliary setting

The auxiliary of the plastic mold is provided with the lifting ring hole, KO hole (top stick hole) and so on

6, dead-angle treatment structure:

When plastic products have dead corners, the mold will also have one or more structures to handle dead corners..Such as sliders, sloping tops, hydraulic cylinders, etc..In most books in China, this kind of mechanism for dealing with dead corners is called the "suction mechanism".

As a matter of fact, it is not difficult to make plastic moulds, no matter how the plastic product may be changed, for the mould to form this plastic product to be of no more structure than the above..And the difference between molds is whether the molds are large or small??The location or manner of each auxiliary part, auxiliary setting, and auxiliary system is different..The methods, structures and sizes of blind corners have changed..Of course, the design experience is particularly important in order to make the die process simple, easy to assemble, long-lived, moderate in price, and the finished product good..Good experience, able to handle design, handling problems, handling changes is also more confident.

You may also like

Send inquiry

Send now